Making the best acoustic decisions when operable walls are being used to divide your space starts with an overall Sound Management Plan that includes all the elements of the room, not just the operable wall.

There are three main acoustical properties that affect the acoustical performance of any room design:

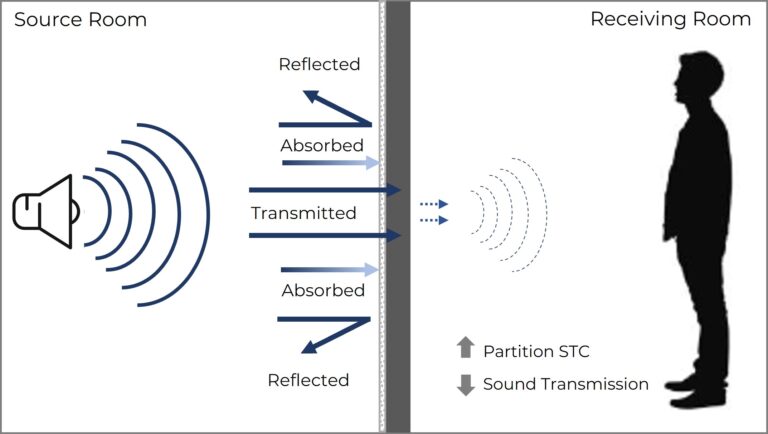

Sound Transmission – how much sound is transmitted through the operable wall and through the room’s adjacent construction. The higher the partition’s STC, the less sound is transmitted through the partition. The sound attenuating capability of an operable wall panel is dependent upon mass, the ability to dissipate vibrational energy, called “damping”, and material stiffness. The more mass a panel has, and the less stiff the mass is to allow it to dissipate vibrational energy, the better an operable wall panel will perform to decrease the transmission of sound from one side of the partition to the other.

Sound Absorption – the process of dissipating sound energy from within a room. Typically, this is accomplished using soft, porous exposed materials to absorb sound energy. Absorbed sound “quiets” the Source Room’s sound energy but has little effect on the Receiving Room’s sound energy transmitted through the partition into the Receiving Room.

The partition’s facing and finish material determines the operable wall’s ability to absorb sound energy. Non-porous materials like vinyl or high-pressure decorative laminate will reflect and not absorb sound energy, while an acoustic fabric or perforated facing materials will. Noise reduction for operable wells tops out at an NRC rating of .65, so if noise reduction is an important part of your sound management plan, careful consideration must be paid to the panel facing and finish material.

Sound Reflection – Reflected sound bounces off the room’s surfaces, staying in the room it was generated in. Reflected sound is perceived as “Live” noise where little sound energy is absorbed by a hard or non-porous partition surface.

These are very different acoustical properties, but each is uniquely important to the overall acoustical performance for any rooms divided by an operable partition.

Your sound management plan needs to consider the following to ensure that you specify and select the correct level of sound control for your acoustic operable wall:

Anticipated Room Sound Levels: Knowing the anticipated sound levels that will be generated by the activities in each room divided by the operable wall will give you a better idea as to the amount of noise reduction to plan for.

Compare the following room usages and their anticipated sound levels:

Room 1 – The operable wall divides two reading rooms in a library where the anticipated levels of noise are very low.

Room 2 – The operable wall divides two meeting spaces where one side hosts a wedding reception with amplified music and the other side hosts a corporate board meeting.

Clearly, these two room scenarios will need vastly different acoustical criteria in order to provide satisfactory noise isolation.

Surrounding Construction: Walls, ceiling material and the plenum above the ceiling to the structure, floor finish materials, adjacent doors or windows and even HVAC ducting that crosses over both rooms in the ceiling plenum – all need to be addressed to ensure that you are receiving the maximum performance from the sound rating of your operable partition.

If you specify an operable wall with a higher STC rating than your adjacent construction, you may be overspending on your partition. If you specify an operable wall with not enough sound control, then you likely will be unsatisfied with the acoustic performance given the activities in the rooms.

Noise Reduction: What are the surface finishes in each room – including the operable partition? Are there a lot of hard surfaces that will reflect sound energy or are there more porous surfaces such as carpet and acoustical ceiling tile that will absorb sound energy? If your room has a high percentage of reflective surfaces, your room will be perceived as noisy, and conversely if your rooms surfaces are porous and absorptive then your room will be perceived as quiet and muffled.

Reference ASTM C423 – Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method

Operable Walls – Laboratory Testing vs. Field Testing

Lab Testing: The most widely accepted standard for testing the acoustical performance of operable partitions is the Sound Transmission Class (STC) Rating per ASTM E90 (2016) – Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements.

Conducted in an accredited NVLAP (National Voluntary Laboratory Accreditation Program) Acoustical Laboratory, the operable wall test specimen shall be large enough to include all the essential constructional elements of the wall should be of normal size, and in a proportion typical of actual use. The test specimen is installed into a controlled opening that has been constructed specifically to eliminate all other factors except the operable partition itself. This gives the best possible acoustical result based on the construction of the operable wall in perfect laboratory conditions. A similar operable wall specimen that would be installed into a real construction environment where the surrounding construction comes into play would not get the same test result.

Field Testing: The most widely accepted field-testing methodology yields a NIC (Noise Isolation Class) rating per ASTM E336 – Standard Test Method for Measurement of Airborne Sound Attenuation Between Rooms in Buildings. This test takes into consideration all of the room’s elements, not just the operable wall. Because of this, there is typically an 8-10 dB difference between the operable wall STC lab test result and the NIC Field test result.

A lower NIC field test result than a lab test STC rating is due to one or both of the following factors:

* Reference ASTM E557 – SOUND ISOLATION BETWEEN SPACES SEPARATED BY OPERABLE PARTITIONS

Conclusion: The best way to ensure success with your space division project is to work with a reputable and experienced operable wall manufacturer and their local installing distributor and have a solid acoustical plan to mitigate any weak flanking paths.

Talk with your local Kwik-Wall Distributor in the design phase of your project. Kwik-Wall distributors are trained and experienced in sound control and can help you avoid any issues that can be difficult or expensive to correct during the later stages of your project’s construction.

Note: Kwik-Wall utilizes the acoustical testing services Riverbank Acoustical Laboratories, an NVLAP-Accredited acoustical laboratory located in Geneva, IL.

If you do not recieve an email,

please check your junk mail folder.