Yes, Kwik-Wall can provide invisible door hinges as an option – available with certain operable wall configurations. Please contact Customer Support for the Kwik-Wall models that offer this feature.

Operable wall engineering has evolved over the last several decades, and manufacturers have learned that given the identical panel, frame and substrate construction materials, a 4” nominal thickness operable wall panel will perform better acoustically than a 3” nominal thickness panel, due to the increased plenum space between the two panel sides. Operable wall panels at 3” nominal thickness top out at an industry best 52 STC, while 4” nominal thickness panels with the same construction and materials can provide up to 56 STC sound control and still be easy to grasp to move manually into position across your room.

Given that operable walls originated from a need to separate space acoustically, the industry is always seeking to improve on acoustical performance as reflected in the higher STC values being offered today with 4″ thick panels.

3″ thick panels were the standard for decades and were designed into storage pockets to create a fixed stacking “footprint” that remains beyond the normal lifecycle of operable walls, creating a continuing need for replacement panels that will retrofit into the existing storage space requirements without a need to modify the existing building to accommodate the larger stacking footprint required for 4″ thickness panels.

4” nominal thickness panels will not always retrofit into a space that was originally designed for 3” nominal thickness panels. If your building has older 3” thickness operable walls, replacing them with new 3” operable walls can save significant building modification costs, while still giving you a high degree of acoustical performance.

Kwik-Wall understands these operable wall panel replacement needs and offers the 2000 Series that can achieve acoustic performance of the replaced walls without affecting the existing stacking depth footprint.

If you have an existing 3″ nominal thickness operable wall that needs to be replaced, give your local Kwik-Wall installing distributor a call.

Need replacement in a hurry? Kwik-Wall’s has the fastest fabrication lead times in the industry.

All operable wall manufacturers engineer and test their track and carrier systems for the actual size and weight/sq. ft. of the partition, based on the specified STC rating panel construction. All major operable wall manufacturers have steel track systems as well as structural extruded aluminum track systems. There is no difference in the weight-carrying capacity between steel and aluminum, given that each is engineered specifically for the weight range of the partition it is supporting.

If you want proof of this, just look to the manufacturers’ product warranty for their track systems. This is where the “rubber meets the road” – if one operable wall manufacturer offers a steel track system warranty period of 2 years and another manufacturer offers a 10-year warranty on their structural aluminum track system, then it makes sense that the aluminum is a better track option just based on the manufacturer’s warranty.

In addition to structural capabilities of a given track system, there are important aesthetic and operational considerations to consider. Some cold-rolled steel tracks are furnished primed painted only, whereas extruded tracks are typically clear satin anodized, not requiring field painting.

Structural aluminum track systems are typically extruded with alignment pin slots, allowing for perfectly aligned joints across track sections.

Anodized aluminum track extrusions have tight tolerances, crisp and clean lines with no dimensional variations that can cause carrier interference at track joints – a major factor in operable wall repair costs.

Anodized aluminum tracks also hold up better to top seal contact over time than painted steel track systems.

At Kwik-Wall, our confidence in the engineered load-bearing capability, durability, operational ease and aesthetics that are built into all of our aluminum track systems, allows us to offer the best track warranty in the industry – 10 years on every manually operated operable wall track system we manufacture!

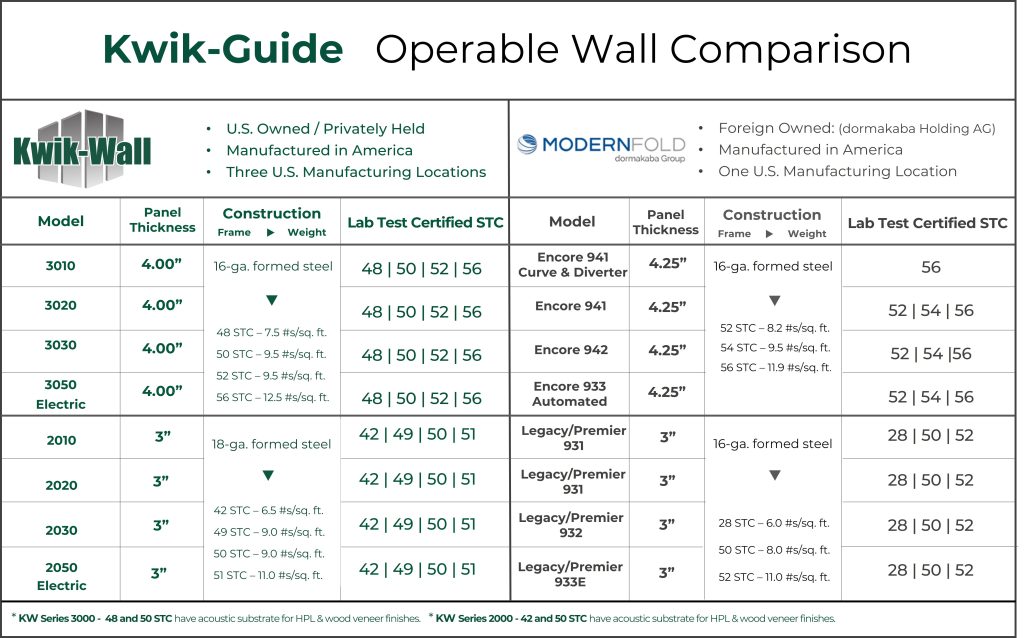

Both Modernfold and Kwik-Wall offer operable wall models at 3” and 4″ nominal panel thickness. Both Modernfold and Kwik-Wall can offer up to an industry-leading 56 STC on their premium 4” nominal thickness models, while their respective 3” nominal thickness panel models are certified at up to 51 STC for Kwik-Wall and up to 52 STC for Modernfold. It is important to note that the human ear is incapable of discerning a one-decibel difference in noise level.

Please see the table below for more comparison details:

Generally speaking, all operable wall manufacturers use a combination of steel, acoustic substrates, insulation and other sound attenuating materials to reduce sound transmission through their panels. The sound attenuating capability of an operable wall panel is dependent upon its mass, the ability to dissipate vibrational energy, called “damping”, and material stiffness. The more mass a panel has, and the less stiff the mass is to allow it to dissipate vibrational energy, the better an operable wall panel will perform to decrease the transmission of sound from one side of the partition to the other.

There are other factors that bear on the ability of an operable wall to keep sound from transmitting from one side to the other, including the sweep seals at the top and bottom of a panel, the interlock at the panels’ vertical joints, pass door panels and intersecting layouts. The more precise the tolerances a panel is fabricated to will also contribute to decreasing the potential joint leakage that reduces acoustic performance.

As a general rule, taking out of the equation the room’s surrounding construction and acoustic flanking paths, the weakest acoustical points in any operable wall are not the actual panels, but rather the panel’s perimeter components – for example, panel joints, top and bottom seal mechanisms, pass doors, door hardware penetrations and final closure components.

The partition’s height and opening width also contribute to the overall acoustic performance. For example, a thirty-foot tall by two hundred feet wide operable will outperform an operable wall of the same STC rating that is ten feet tall by 30 feet wide, just because the percentage of panel construction relative to the partition’s weaker perimeter areas is higher.

(See Acoustics under the Learn More tab here for more information on designing for operable wall acoustics)

Standard turnaround on shop drawings is approximately two weeks from the date a purchase order is received. Expedited shop drawings are available on a limited basis, depending on the current drawing backlog. If specific information is needed about a project (such as overhead support locations, pocket clearances, etc.), please contact Kwik-Wall – We can typically provide this information over the phone or via email, which will allow the coordinating trades to continue working while your project is waiting to be drawn.

Please reference the Operable Wall Acoustics tab in Learn More for information on understanding operable wall acoustics.

Kwik-Wall extruded aluminum track comes standard with a durable clear satin anodized finish, but custom RAL powder coating is available. Please contact your local distributor for details and cost.

A complete guide to our color selectors can be located under our Finishes in our Downloads Tab on the Kwik-Wall website.

From our website’s main navigation tabs, select Downloads then click the down caret to select Finishes, then navigate to the product group you are interested in to view all finish samples for that product group, You will be able to order samples from the Order Samples Button under each finish selector card.

The max height per panel depends on the operable wall series and specific configuration model, but Kwik-Wall 3000 series individual panel configurations are available to a maximum of 30 ft. tall.

Please see product downloads on selected Kwik-Wall models for more information.

CAD details for our operable and glass wall systems are located under Downloads > Product Downloads > select product group. If you don’t find what you are looking for please contact your local authorized Kwik-Wall Distributor, or contact Kwik-Wall Sales Support from the General Inquiries button on the Contact Us page.

BIM models are available via a link on the Products Download Page.

System weight varies depending on the model and STC ratings, and is listed as lbs. / square foot. This information is contained within the Product Downloads and in the product specifications, which can be viewed or downloaded from our website under Product Downloads from the top navigation tab.

While some leading operable wall manufacturers are struggling to provide products in under 6 months, Kwik-Wall prides itself in leading the operable wall industry with the fastest production lead times – averaging under 10 weeks after release for fabrication.

Fabrication lead times can fluctuate based on your project’s specific requirements, but Kwik-Wall is committed to maintaining the fasted lead times in the industry.

All wall repair and accessory requests are handled by your local distributor. Find A Distributor

Kwik-Wall provides technical assistance for layout and configuration designs, no matter how complex. Your local Kwik-Wall distributor is trained to provide design and layout assistance and will walk you through sound control decisions, layout options, operational configuration options, panel storage options, and how your Kwik-Wall operable wall connects to your building’s structure.

If you are unsure of your building structure’s ability to handle the weight of your operable wall, just ask your distributor for information on Kwik-Span™ – our proprietary, pre-engineered self-support truss system that will eliminate the need for structural beam calculations, fabrication, and installation requirements of a typical operable wall steel support.

Kwik-Wall offers a multitude of options and accessories for our complete line of space division products., including but not limited to:

Yes, both Kwik-Wall 3000 and 2000 Series operable walls can be electrically operated – Model 3050 Electric and Model 2050 Electric are continuously hinged electric operation – find more information on our website under the Downloads Navigation menu at www.kwik-wall.com > Downloads > Product Documents.

In addition, certain Kwik-Wall Luminous Glass Walls can be equipped with programmable, self-driving/locating panels. Consult your local Kwik-Wall distributor for details and design assistance.

Kwik-Wall Operable walls are made in one of three U.S. manufacturing facilities: Our primary production facility is located in Springfield, Illinois, and our newly opened satellite production facility is located in Mt. Pulaski, Illinois.

Our Accordion partitions are manufactured at our Darien, WI production location.

Contact your local Kwik-Wall distributor – they would be happy to show you some of their completed Kwik-Wall installations.

You can also browse through our gallery by product group on our website. With more than 60+ years of experience in transforming space to create opportunities, Kwik-Wall has a wealth of projects to draw inspiration from.

If you do not recieve an email,

please check your junk mail folder.