Scott Staedter, Kwik-Wall Vice President of Strategy addressing the CSI National Conference, 2023

Operable Partitions or Folding Panel Partitions provide acoustic separation and space flexibility for building owners and tenants. Commonly specified by architects for schools, hotels, convention centers, offices, government facilities and even residential applications, manufacturers, general contractors, and design/builders continue to see consistent errors within MasterFormat Section 10-22-26 (Operable Partitions) and 10-22-39 (Folding Panel Partitions) that lead to confusion and post-bid project fulfillment issues.

In this Kwik-Tips™ blog post from Kwik-Wall, we address the common errors that can occur in today’s operable partition specifications.

For projects in North America, the manufacturers below can provide a full range of acoustically rated operable partitions achieving common 52 STC and above in different panel constructions:

Advanced Equipment Corporation | Kwik-Wall Company | Hufcor by Kwik-Wall | Modernfold | Moderco

Specifiers should also know that in June 2023, U.S. operable wall manufacturer Kwik-Wall Company purchased Hufcor’s intellectual property rights to North America and can now provide HUFCOR 600 Series operable walls; FlexTact (tactical training operable wall system); and Unispan (partition self-support truss system). Listing both Kwik-Wall and Hufcor by Kwik-Wall products in your specifications ensures both Kwik-Wall legacy 2000 and 3000 series and HUFCOR 600 Series operable walls are appropriate for your specific project applications.

Specifying comparable products and features from this list of manufacturers will ensure that market-proven, top-quality suppliers can bid on the specifications without confusion.

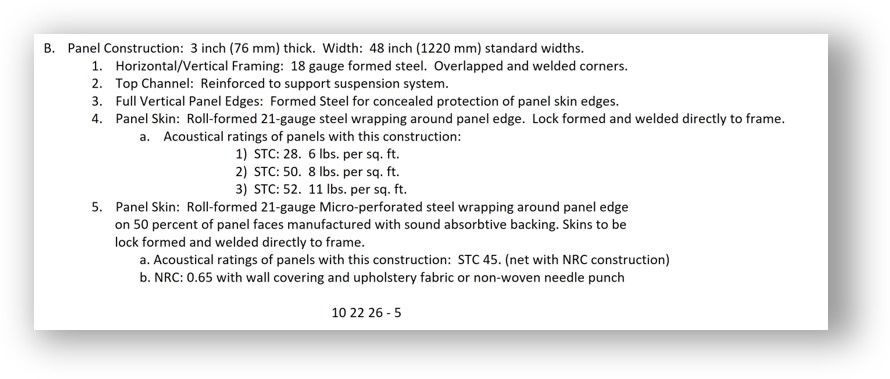

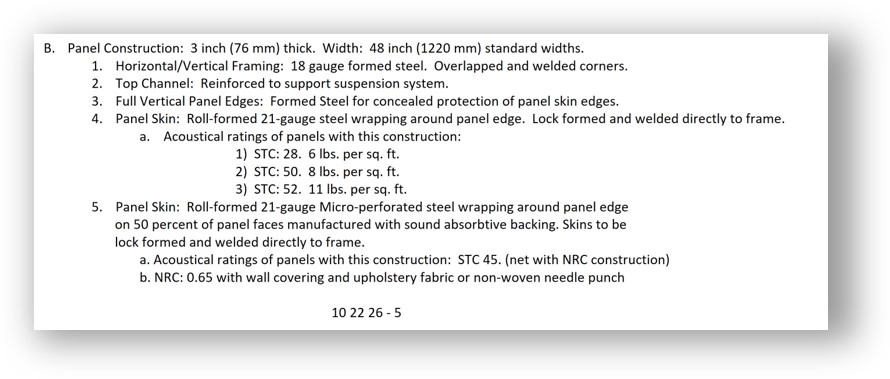

Since increased STC ratings are achieved through increasing the mass and thickness of panels, these two elements (High STC and low panel weight) conflict. With STC ratings of 50 and above, from all manufacturers, the weight of the partition will increase. Listing a particular weight “not to exceed”, along with a high STC, will inevitably have incompatible, conflicting performance criteria.

The same holds true for sound absorption properties or Noise Reduction Coefficient (NRC). NRC is basically what percentage of sound hitting the face of a partition is absorbed by the surface and not reflected into the source room. The more absorption a movable partition requires, the lower the STC value of the wall. For example, Kwik-Wall has seen specifications that require a 56 STC (top North American manufacturers’ acoustical rating) and a 0.80 NRC. These don’t exist from any manufacturer, even though both manufacturers and other third-party specification tools allow these selections.

The same holds true for sound absorption properties or Noise Reduction Coefficient (NRC). NRC is basically what percentage of sound hitting the face of a partition is absorbed by the surface and not reflected into the source room. The more absorption a movable partition requires, the lower the STC value of the wall. For example, Kwik-Wall has seen specifications that require a 56 STC (top North American manufacturers’ acoustical rating) and a 0.80 NRC. These don’t exist from any manufacturer, even though both manufacturers and other third-party specification tools allow these selections.

No North American manufacturer listed above provides higher than a 51 STC that can also achieve a 0.65NRC with standard perforated steel faces and common woven finishes. Most are in the 48STC/0.65NRC maximum range. Additionally, no operable partition manufacturer can provide a higher NRC than 0.65 within their base products, unless they apply an additional stretch fabric sound absorption system to the panel face.

No North American manufacturer listed above provides higher than a 51 STC that can also achieve a 0.65NRC with standard perforated steel faces and common woven finishes. Most are in the 48STC/0.65NRC maximum range. Additionally, no operable partition manufacturer can provide a higher NRC than 0.65 within their base products, unless they apply an additional stretch fabric sound absorption system to the panel face.

Additionally, the floor flatness and floor level conditions can vary greatly on projects, especially when combining slab-on-grade and elevated slabs. Elevated slabs are designed with camber to settle after pour and deviations in the planned movement over time do occur. Kwik-Wall professionals have experienced floors that have had up to 3” of variance from one end of the opening to the other.

More typically, if the overhead structure deflects 1.5” and the floor has 1” of variance, then the partition’s bottom seals will require a minimum of 2.5” of travel to absorb these building movements. Often Kwik-Wall sees generic language within the operable partition specification calling out “manufacturer’s standard mechanical seal.” Those standard seals typically provide up to 2” of travel among the manufacturers’ products. A specifier should list the minimum distance of bottom seal travel based on both overhead structural deflection and floor-level requirements and list manufacturers that have proven bottom seals that can meet these requirements.

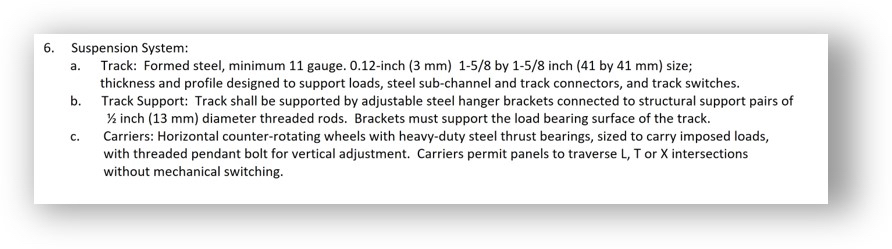

Moreover, many specifications for track systems don’t match the ones shown on the architectural drawings. For example, the floor plans will show a typical aluminum track with right-angled intersections (X, T, L configurations), yet the specification requires a radius, curve and divert system. Rule of thumb is that steel tracks are not specified with X L or T intersections using counter rotating wheels as demonstrated below. Those are aluminum track systems. Specifiers should have a quick consult with their trusted operable partition rep to make sure the track type is consistent with the plans.

Kwik-Wall recommends listing both “steel and aluminum suspension per project configurations” be included within Part 2 – Product performance requirements.

Kwik-Wall recommends listing both “steel and aluminum suspension per project configurations” be included within Part 2 – Product performance requirements.

LEED v.4 IEQ standards and ANSI S.12.60 specifically outline optimal acoustical performance levels for wall and corridor designs to achieve optimal learning environments, specifiers should be focused on proven acoustical performance of glass operable partitions without bogging down the specification with exterior application performance criteria for best outcomes – especially in school design – where optimal wall performance between classrooms and corridors is minimum 45 STC.

LEED v.4 IEQ standards and ANSI S.12.60 specifically outline optimal acoustical performance levels for wall and corridor designs to achieve optimal learning environments, specifiers should be focused on proven acoustical performance of glass operable partitions without bogging down the specification with exterior application performance criteria for best outcomes – especially in school design – where optimal wall performance between classrooms and corridors is minimum 45 STC.

Does the door require an automatic closure or not? Do the doors require locks and panic override of these locks? Recently, we were asked to provide a door that could be locked on both sides but also required panic operation in both directions, since the egress direction would change based on the operable partition setup configuration. How is that feasible given the lock would be overridden? The point is that a timely call to your trusted operable partition consultant or local representative is warranted when working on a project with pass doors to dial in the appropriate accessories and avoid confusion post-bid time.

Conclusion: It is important to review the operable partition specifications thoroughly and consult industry standards, manufacturer guidelines, and applicable building codes to avoid these common errors. Working closely with design professionals and manufacturers can help ensure accurate and comprehensive specifications.

Kwik-Wall operable partition experts can assist you directly to help with all of your specification questions. Call us or email us today if you need a quick consultation or if you are looking to solve a design challenge. Want to learn more?

Subscribe to our newsletter – Kwik-TakesTM– a quarterly quick read of helpful operable wall specifications and design tips.

.

If you do not recieve an email,

please check your junk mail folder.